James W. Heffel

University of California,

Riverside, CE-CERT

Douglas C. Johnson

Cal-Draulics

Carroll Shelby

Carroll Shelby Enterprises

(re-published

2003 by permission)

ABSTRACT

This paper describes the details of converting a gasoline

powered 427 Shelby Cobra to run on gaseous hydrogen. The purpose of this

project was to design a vehicle capable of beating the current land speed

record for hydrogen powered vehicles.

The vehicle uses a modified 427 Ford FE engine as the power

plant with a specially designed electronic fuel injection system for metering

the hydrogen. The engine was designed to produce near zero emissions (<10

ppm NOx) at approximately 270 HP using a lean burn, “quality controlled”,

fueling strategy (no pollution control devices are utilized).

INTRODUCTION

In the early 1990’s, a long time hydrogen advocate named

Ben Jordan built a trophy to be given each year to the fastest hydrogen

powered vehicle. The competition is held at the Bonneville Salt Flats in Utah.

The current record for this competition is 108.268 mph held by AHA member,

Terry Young of Middle Tennessee State University. Since there is currently no

official class for hydrogen fueled vehicles, the vehicles are run in what is

called a “time only” category 1). The goal was to build a vehicle capable

of beating that record and win the Ben Jordan trophy

BACKGROUND

Hydrogen is widely regarded as a promising transportation

fuel because it is clean, abundant, and renewable. In a gaseous state, it is

colorless, odorless, and non-toxic. When hydrogen is combusted with oxygen, it

forms water as the by-product. Due to hydrogen’s high flammability range, it

can be completely combusted over a wide range of air/fuel ratios. Unlike

gasoline, which if combusted outside its optimal air/fuel ratio will produce

excess carbon monoxide (CO) and hydrocarbons (HC), hydrogen does not have a

carbon element and therefore will not produce those toxic gases. Like gasoline

however, when hydrogen is combusted in air (mixture of oxygen and nitrogen)

the temperature of combustion can cause the formation of the nitric oxidizes (NOx).

Hydrogen however has an advantage over gasoline in this area because it can be

combusted using very high air/fuel ratios. Using a high air/fuel ratio (i.e.

combusting hydrogen with more air than is theoretically required) causes the

combustion temperature to drop dramatically and thus causes a reduction in the

formation of NOx. Unfortunately, the use of excess air also lowers the power

output of the engine. [1]

Over the past eight years, the University of

California – Riverside, College of Engineering – Center for Environmental

Research and Technology (CE CERT) has been experimenting with improving the

performance of hydrogen-powered vehicles. Most of these methods have involved

using superchargers [2] and turbochargers [3] to bring up the power. While

these devices have worked to some degree, it was felt these methods were too

complicated of a solution to a simple problem. The authors of this paper

believed the simple solution was to just make the engine bigger. Or use a car

that has “way more engine” (Horsepower) than it really needs. The author

of this paper chose the latter - and what better car for this than the Shelby

Cobra?

The Shelby Cobra

The Cobra was the brainchild of racecar driver, Carroll Shelby. In 1962,

Shelby worked a deal with Britain’s AC Cars and America’s Ford Motor

Company to develop the quickest production vehicle in the world. Initially,

street Cobras were powered by stock HiPo 260 Fords, but were soon replaced

with HiPo 289s rated at 271 HP. In January 1963, the Cobra won

its first race at the SCCA divisional race at Riverside

Speedway. The racing legacy of Carroll Shelby’s Cobra had begun. Over the

next few years, the 289 Cobra dominated the racing circuit. In January 1965,

Shelby started the production of the 427 Cobra, which used a Ford 427 side-oiler.

Although, the 289 was by far the biggest winner, whatever the 289 did, the 427

did better. The 427 Cobra was and remains the “world’s quickest production

car”. That was proven with 0 – 60 mph times of 3.8 seconds, 0 – 100 mph

in 10.6 seconds, and 0 – 100 and back to a dead stop in less than 14

seconds. [4]

In 1996 Shelby American, Inc. announced the reintroduction

of the Shelby 427 S/C Cobra as the CSX4000 component vehicle. The cars are

sold as “rollers” (less the engine and transmission).

In a chance meeting with Carroll Shelby, James Heffel

discussed the proposed project with Carroll and with little hesitation; agreed

to provide one of his new Cobras for this project.

VEHICLE CONVERSION

The Cobra roller (Vehicle Serial Number CSX 4201) was picked up from Shelby

America, Inc. in Las Vegas, Nevada and the engine (an all aluminum 427 cubic

inches replica of the original Ford FE side-oiler) was picked up from Shelby’s

facility in Gardena, California on August 19, 2000.

Figure 1 – Picture of car as delivered

(no paint engine or transmission)

The car and engine were delivered to Cal-Draulics of

Corona, California, where the hydrogen conversion was to be conducted. The

project was broken down into the following five tasks:

Task 1. Set up the car to run on gasoline.

Task 2. Paint the car.

Task 3. Install the roll cage and fire suppression system

Task 4. Do a car and driver checkout run (on gasoline) at El Mirage Dry Lake

Bed.

Task 5. Convert the car to run on hydrogen.

Task 6. Do a record attempt at Bonneville Salt Flats (Oct. 2000).

With limited funds and limited time, the following set of conditions were

developed:

1. Do it as simple as possible

2. Do it as quickly as possible

3. Do it as economically as possible (and still beat the

record)

Tasks 1, 2, and 3

The first order of business was to get the engine and

transmission mated together and then installed this assembly into the car.

Instead of the using a 4-speed “top loader” transmission originally used

in the 1965 Cobras, a 5-speed Tremec TKO manual transmission was chosen. To

comply with the Bonneville National rules, a steel shatter shield was required

in place of the aluminum bellhousing. For this, a shatter shield made by

Lakewood was used. To mate the shatter shield to the transmission, an adaptor

plate, made by McLeod, was used. A Centerforce, double acting clutch and

flywheel were employed to provide positive engagement between the engine and

transmission. Wayne’s Engine Rebuilding, Inc. of Riverside, California,

balanced the clutch, disc, and flywheel. The clutch fork and throw out

bearing, normally used on 1970 Ford Broncos, was utilized to finalize the

transmission assembly.

To ease the installation of the transmission/engine, the

radiator was removed and the engine/transmission assembly was carefully

lowered into the car as a single unit. The transmission was secured to the

chassis using a transmission mount (new) from a late model Ford Mustang and

the engine was secured to the chassis using motor mounts from a 1965 Ford

Galaxy Station Wagon (also new). To connect the output shaft of the

transmission to the input shaft of the Dana 44 differential, Golden State Axle

of Corona, California fabricated a special 13-inch long driveshaft.

Following the installation of the engine and transmission, the car was sent

to the paint shop where Tony Avila, Tony, Jr. and Herman Broom gave it the

flashy red paint job with two white racing stripes

down the center. Tony, Herman, and Tony, Jr. also assisted

in the installation of the hydrogen storage tank. From the paint shop the car

went back to Cal Draulics where a small gasoline tank was installed in the

trunk of the car so it could be tested on gasoline to verify all the

components (engine, transmission, clutch, brakes, etc) were operating

properly. Once this was completed, the car went to Cook Motorsports in Norco,

California, where the installation of the roll cage and fire suppression

system was conducted. All these tasks were completed by October 7, 2000.

Task 4

On October 8, the car was taken to El Mirage Dry Lake Bed

in the high desert of California to do a test run on gasoline. A speed of 135

mph was recorded with James Heffel driving. This was not a maximum speed run.

This run was performed to verify that both the car and the driver were capable

of operating at speeds above the current hydrogen record, prior to attempting

this using hydrogen.

Task 5

Hydrogen Fuel Injection System

One of the primary problems encountered in the development

of operational hydrogen engines is pr mature ignition (pre-ignition). Pre

-ignition occurs when the cylinder charge becomes ignited before the ignition

by the spark plug. If this condition occurs when the intake valve is open, the

flame can travel back into the induction system. Various fuel injection

methods have been experimented with over the years. These methods have

included carbureted systems, which mix the air and fuel at a central point

upstream of the intake valves; port injection systems that inject the fuel

into the air stream near the intake valve; and direct injection systems that

inject the fuel directly into the combustion chamber. For carburetor-type

systems, which can have a substantial amount of air and fuel in the manifold,

pre-ignition can have a devastating effect. Port injection systems, which tend

to have less fuel in the manifold at any one time, can minimize this effect.

Running lean (excess air) and precisely timing the injector opening and

closing times (tuning the system), can virtually eliminate pre-ignition from

occurring. Direct injection system can eliminate pre-ignition in the intake

manifold, however it does not necessarily eliminate it in the combustion

chamber. Direct injection systems also require higher fuel pressure and tend

to be a little more complicated than the other two methods. The method that

was chosen for this project was the port injection system. The fuel injectors

used to meter the fuel are solenoid operated, pulse-width modulated, sonic

flow injectors especially designed for gaseous fuels. These injectors were

provided by IMPCO Technologies, Inc. of Irvine, California. A cross-section

view of this injector is shown in Figure 2.

Figure 2 – Cross-section of injector

Numerous design options were considered with regard to the

fuel injection system. Knowing little time was available to fine-tune the

system (and thus totally eliminating the possibility of pre-ignition), we

chose a design that would be somewhat tolerant to an occasional pre-ignition

event. This design involved replacing the existing intake manifold (made for a

four-barrel carburetor), with an intake manifold designed to use four 2-barrel

Weber carburetors.

Figure 3 – Intake Manifold

This new manifold provided short, single runners for each cylinder. For

each runner, a 1 ½ inch tall injector body was designed and fabricated to

house the injectors.

Figure 4 - Injector body

Each injector body was designed to incorporate a ¼ inch

tube that transported the hydrogen from the injector outlet to within an inch

of the intake valve. This was to minimize the amount of hydrogen that would be

in contact with the air in the runner. That way if pre-ignition was to occur,

damage to the intake system would negligible.

Additionally, a “quality” control fuel strategy was

selected as the basis for metering the hydrogen. A distinct advantage of using

hydrogen as a fuel, with its wide range of flammability, is the fuel-to-air

ratio or the “quality” of the charge mixture can easily be varied to meet

different driving conditions or loads. This is similar to the strategy used by

diesel engines. In contrast, for a gasoline engine, the fuel-to-air ratio must

be kept more or less constant throughout the driving range. In other words,

the “quantity” of the charge is controlled. Using a “quality”

controlled strategy enables the engine to operate at a constant

wide-open-throttle (WOT) position throughout the power band (just add more

fuel for more torque). To communicate to the Engine Control Computer (ECC) the

amount of fuel desired, a throttle position indicator was connected to the gas

pedal (not to the throttle plates since they are normally at WOT). Basically

the gas pedal acted as an electronic sensor that would send a fuel demand

signal to the ECC. The ECC would base how long it would hold an injector open

on this signal.

To facilitate the starting of the engine, a choke

(butterfly valve) was designed and fabricated for each injector body.

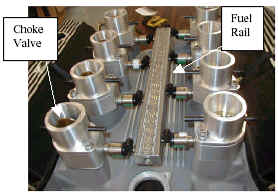

Figure 5 – Choke Assembly and Fuel Rail

All eight chokes are linked together and centrally controlled by a

hand-operated cable located in the cockpit of the vehicle. Once the engine

started, the chokes are pulled to the wide-open position and the “quality”

controlled fuel metering strategy is implemented.

Since the design of this system allows the flow of hydrogen and air to each

cylinder to be independent of each other, any occurrence of pre-ignition in

one cylinder would not influence (ignite) the air/fuel mixture of another.

Whereas with systems that manifold all the intake runners together, a

pre-ignition in one cylinder can light the whole intake manifold on fire. To

maximize the airflow to engine, each manifold runner, intake port, injector

body and throttle body

were match-ported. See Figure 6.

Figure 6– Match porting injector with intake manifold

To supply fuel to each injector, a single fuel rail was

designed and fabricated. See Figure 5. This fuel rail contains a port for each

of the fuel injectors.

Hydrogen Storage

The hydrogen storage tank was provided by IMPCO

Technologies,

Inc. of Irvine, California.

Figure 7 – Hydrogen storage tank

The tank has a Type IV rating and uses a plastic bladder

wrapped with high strength composite graphite. The tank has a water volume of

87 liters and is rated up to 3,600 psi. At 3,600 psi, the tank holds 590 SCF

of hydrogen, which is equivalent to 1.4 gallons of gasoline. At 200 HP, this

tank is emptied in about 5 minutes.

Hydrogen Ancillary System

The hydrogen ancillary system consists of a high flow

capacity pressure regulator, a manual shut-off valve, a solenoid operated “on/off’

valve, three pressure gauges and a fuel line. The pressure regulator, provided

by Control Seal Controls, is used to reduce the pressure of the fuel in the

storage tank (3600 psi) to a useable fuel rail pressure of 100 psi. Upstream

of this valve is a manually operated ball valve and pressure gauge. A

quarter-turn of this valve will shut off the hydrogen in the event of a leak

or fire. The pressure gauge reads the pressure of the fuel in the storage

tank. Downstream of the pressure regulator is a solenoid-operated valve and a

second pressure gauge. The solenoid valve is controlled via a switch mounted

in the cockpit of the vehicle. This valve is a “normally closed” valve,

meaning in the event of a power failure this valve will automatically close.

This pressure gauge reads the pressure at the outlet of the pressure

regulator. The third pressure gauge is located at the engine fuel rail and

reads fuel pressure at the engine.

The Engine

The engine used for this car is an all aluminum replica of

the original 427 Ford side-oiler. Even though this powerful engine would have

met the needs of the project, it was decided to bore and stroke it to 526

cubic inches (4.375” x 4.375”) and give it a 12:1 compression ratio This

engine was dynamometer tested by Mike LeFevers at 600HP (at 6,100 rpm) using

gasoline.

Performance

The theoretical maximum power output from a hydrogen engine

depends on the fuel injection method used. This is because hydrogen will

displace a large portion of the incoming air, and thus limiting the amount of

air that will enter the combustion chamber. For example, the stoichiometric

air/fuel ratio for hydrogen 34:1. For this mixture, hydrogen will displace 29%

of the combustion chamber, leaving only 71% for the air. As a result, the

energy content of this mixture will be 15% less than it would be if the fuel

were gasoline (since gasoline is a liquid, it only occupies a very small

volume of the combustion chamber, and thus allows more air to enter). Since

both the carbureted and port injection methods mix the fuel and air prior to

it entering the combustion chamber, these systems limit the maximum power

obtainable to 85%

of that of gasoline engines (rough order of magnitude). For direct

injection systems, which mix the fuel with the air after the intake valve has

closed (and thus the combustion chamber has 100% air), the maximum output of

the engine can be 15% higher than that for gasoline engines (again, rough

order of magnitude).

Therefore, depending on how the fuel is metered, the

maximum output for a hydrogen engine can be either 15% higher or 15% less than

that of gasoline if a stoichiometric air/fuel ratio is used. However, at a

stoichiometric air/fuel ratio, the combustion temperature is very high and as

a result it will form a large amount of nitric oxides (NOx), which is a

criteria pollutant. Since one of the reasons for using hydrogen is low exhaust

emissions, hydrogen engines are not normally designed to run at a

stoichiometric air/fuel ratio.

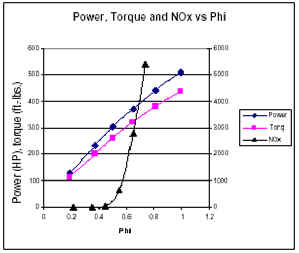

Shown in Figure 8 is a plot of NOx formation versus

equivalence ratio phi (equivalence ratio is the actual air/fuel ratio divided

by the stoichiometric air/fuel ratio. If the value for phi is less than one,

the mixture has excess air and therefore is lean. If the value for phi is

greater than one, the mixture has excess fuel and therefore rich).

Figure 8 – Power, torque and NOx vs. phi

From this plot is can be seen that in order to keep the NOx

formation low, a phi of 0.45 (A/F of 80:1) or less is required (above a phi of

.45, NOx emissions increase very quickly as the phi increases). Also shown on

this graph is a relationship of power (based on an engine speed of 6,100 rpm)

and torque as phi changes. At a phi equal to 1 (stoichiometric), this engine

would theoretically produce a maximum power and torque of 510 HP and 440

ft-lb, respectively. However at this power output, the engine would be

producing a large amount of NOx emissions. From Figure 8 it can be seen that

the maximum “clean” power (at 6,100 rpm) and torque (i.e. near zero

pollution without any exhaust gas after-treatment or pollution control

devices) would be about 270 HP and 230 ft -lb, respectively. This would occur

at a .45 phi.

Figure 9 – Compression vs. Air/Fuel mixtures

Running at a phi of 0.45 also has other benefits besides reducing NOx

emissions. The first is its “effective octane” rating is increased (i.e.

its ability to operate at higher compression ratio increases). As it can be

seen in Figure 9, hydrogen can tolerate compressions of 15:1 at a 60% lean

mixture (.4 phi). Whereas, at a stoichiometric or a chemically correct mixture

(CCM), it can only tolerate compression ratios slightly above 8:1. Limiting

the maximum fueling rate to a phi of .45 (based on low emissions), the engine

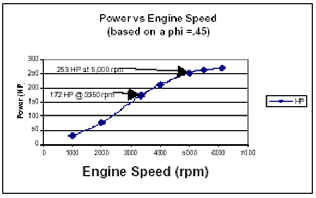

will have a power vs engine speed curve similar to the one shown in Figure 10.

Figure 10 – Power vs Engine Speed (at phi = .45)

Hydrogen’s simple atomic structure along with its ability to burn under

ultra-lean conditions also contributes to a ratio of specific heat closer to

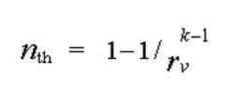

1.4 (ideal gas). Both the compression ratio and the ratio of specific heat are

the two variables in the calculation of thermodynamic efficiency (see equation

1).

Where rv = the compression

ratio and k = the ratio of specific heats

Equation 1

The higher these values, the higher the thermodynamic efficiency of the

engine. The lean air/fuel mixtures also lower the chances of pre-ignition

occurring

Valve Timing

The camshaft that came with the engine was designed to

produce its maximum power at high engine speeds. It was ground to have 48

degrees of valve overlap and 268 degrees of duration with a 0.74-inch valve

lift at .050-inch tappet lift. This type of grind will typically produce

excellent airflow (high volumetric efficiency) at high engine speeds, at the

expense poor air dynamics at the lower engine speeds. For gasoline fueled

engines, this typically means low efficiencies, poor idle, and high emissions.

For racing purposes, this compromise for high engine speeds is worth it.

Drivetrain

As mentioned earlier, a Tremec TKO 5-speed manual

transmission was installed. This transmission has the following gear ratios:

1 st gear: 3.27:1

2 nd gear: 1.98:1

3 rd gear: 1.34:1

4 th gear: 1:1

5 th gear: .68:1

The Cobra came with a Dana 44 differential with a 3.54:1

gear ratio and a set of B. F. Goodrich P295/50R15 rear tires that have a

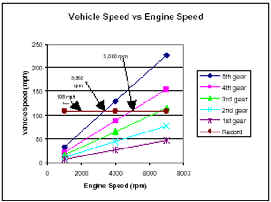

26.1-inch diameter. Figure 11 shows a plot of the vehicle speed versus engine

speed for this drivetrain.

Figure 11 - Vehicle speed versus engine speed

In order to exceed the current record of 108.268 mph, the

vehicle would need an engine speed of more than 5,000 rpm, if the transmission

is in 4th gear, or an engine speed of more than 3,350 rpm if the transmission

is in 5 th gear. As can be seen in Figure 10, the engine will produce 172 HP

at 3,350 rpm and 253 HP at 5,000 rpm. Both of these power levels are well

beyond the estimated power level, of 140 HP, needed to propel the vehicle at

speed faster than the current record speed of 108.268 MPH.

Ignition System

The engine came with a Mallory Magnetic Breakerless

distributor that uses mechanical weights for timing advance (maximum of 32

degrees). This system is mechanically linked to the engine through a gear on

the camshaft. Each time the camshaft completes one revolution the rotor of the

distributor also makes one revolution. On the same shaft as the rotor are 8

vanes, one for each cylinder (see Figure 12).

Figure 12 - View distributor vanes

Each time one of these vanes pass by the magnetic pick up

sensor on the distributor, the coil (single) discharges, sending a high

voltage signal through the coil wire to the distributor. This signal would

then be distributed to the proper cylinder via the rotor, rotor cap and spark

plug wire. This type of ignition system works well for engines that do not

have an Engine Control Computer (ECC). However, for this project an ECC was

used and therefore another method for ignition timing was employed.

Engine Control Computer (ECC)

A programmable engine control computer (ECC) was utilized

to control fuel (sequential injection) and ignition timing. For the ECC to

accurately control these two parameters, it needs to know when a piston

(typically piston number one) is at TDC and if it is at TDC of its intake

stroke or TDC of its power stroke. To do this, two sensors were used: one on

the crankshaft (REF) and one on the camshaft (SYNC). For the REF signal, a

Ford 36 minus one tooth gear was installed, along with a Variable Reluctance

Sensor (VRS). Each tooth, and corresponding blank space, of the gear generates

one complete sine wave as it passes the VRS sensor. Each sine wave represents

10 degrees of crank rotation. Each time the missing tooth appears at the VRS

sensor (once every 360 degrees of crank rotation), the sine wave is altered as

shown in Figure 13. This altered sine wave indicates to the ECC that the

reference piston is at TDC. This however is not enough information to initiate

the fuel and ignition events for sequential injection. The ECC still needs to

know what cycle (intake stroke or power stroke) the piston is on. For this

information, a camshaft position sensor is needed to provide the SYNC signal.

Modifying the Distributor to Provide a SYNC Signal

For this project it was determined that the easiest way to

generate a SYNC signal would to be to modify the existing Mallory distributor

as opposed to mounting a sensor directly on the camshaft. As mentioned

earlier, the Mallory system uses 8 vanes on the distributor shaft to reference

the compression stroke of each cylinder (using a magnetic pickup sensor).

Removing 7 of these 8 (see Figures 14 and 15) vanes would in essence provide a

SYNC signal for the compression stroke of the reference piston (again, piston

number 1). The output signal from this system is a square wave.

Figure 14 – Grinding out 7 of the 8 vanes.

Figure 15 – View of Distributor with missing vane

Using the two methods described above to determine the SYNC

and REF signal, the ECC is now able to accurately determine when piston number

1 is approaching TDC of its compression stroke and thus time the opening of

the fuel injectors and spark ignition. Transmitting the electrical current to

the spark plug can be done numerous ways. The preferred way would be to use a

“coil and plug” for each cylinder. This method however is fairly expensive

and not necessary for this project. A simpler and less expensive method was

used for this project. This method utilized the existing distributor system

(rotor, cap, wires, etc) to transmit the current to each of the spark plugs

(similar to the original system. The main difference with the new system is

that ignition advance is controlled directly by the ECC and not by centrifugal

weights in the distributor.

Task 6

The October meet at the Bonneville Salt Flats was cancelled due to rain and

therefore no record run was attempted. A record attempt is planned for the

next meet in August of 2002.

DISCUSSION

The design approach for this project was heavily influenced by budget and

time constraints. Therefore, not all the design decisions were based on the

best option available, but the best option that would work within our

constraints. The vehicle described in this report was successfully designed

and built under the given time and budget constraints. Whether or not it has

met the design goal of this project, that is, setting a new land speed record

for hydrogen powered vehicles will be made clear at the next event.

Figure 16 – View of Engine Converted to Run on Hydrogen

Figure 17 – View of Cobra. Painted and ready to go.

ACKNOWLEDGEMENTS

The authors would like to thank the following

organizations/people that have provided help and/or funding for this project:

Shelby American, Inc., Cal-Draulics, SunLine, IMPCO, KWJ

Engineering ,Circle Seal Controls, Clean Air Now! (CAN!), K & N Filters,

Ben Jordan, Bob and Dolores Zweig, Tony Avila, Anthony Avila, Herman Broom,

Douglas Kruse, Paul Shepherd, Mike Guidry, Larry Dashield (College of the

Desert), Bob Marsh, Tom D’antonio, Gary Davis, Deena Heffel, Jeanette

Johnson

GLOSSARY

1. FE engine. The FE designation refers to

passenger-car

and light-truck big block engines built by Ford from

1958 to 1971.

2. Side-oiler. A side-oiler engine has an oil gallery

along

the left side of the block that feeds the main bearings

before the cam bearings.

3. HiPo engine. Engine designation for High

Performance.

REFERENCES:

1. Norbeck, J.M.; Heffel, J.W.; Belinski, S.E.;

Durbin,

T.; Bowden, J.P. Tabbara, B.; and Montano, M. (1996)

Hydrogen Fuel for Surface Transportation. Society of

Automotive Engineers, Warrendale, PA.

2. Heffel, J.W., and Norbeck, J.M. (1996) Evaluation of Supercharged

Hydrogen Fueled Ford Ranger

Trucks. CE-CERT Technical

Report 95:AV:043F.

3. Heffel, J.W., and Norbeck, J.M. (1995) Evaluation of UC Riverside’s

Hydrogen Powered Truck. Proc. Of the 6th Annual National Hydrogen Association

Meeting, Alexandria, VA, March, pp. 85-111.

4. Gabbard, A., (1988) Fast Fords. HP Books.

5. Ricardo, H., The High-Speed Internal Combustion Engine, Blackie and Son,

London, 1960.

Jim Heffel is principal

engineer for the University of California Riverside CE-CERT

hydrogen research program. He has published many papers on hydrogen

applications and was a key contributor to a fuel cell engine training manual

coordinated by College of the Desert. The manual will be used by A/C Transit

of Oakland California to familiarize their technicians on the properties of

hydrogen and it’s use in fuel cell busses.

Jim

continues refining the Shelby Cobra for another attempt at the land speed

record for an alternative fuel vehicle.

For more information see www.cert.ucr.edu